Revving up your lawn care game means not only choosing the right mower but also selecting the perfect deck to tackle your turf with precision and power.

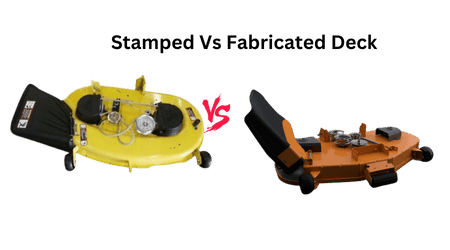

It’s time for an epic showdown: Stamped vs. fabricated deck. In one corner, we have the finesse of stamped decks, designed for a seamless cut.

In the other corner, the brute strength of fabricated decks, is built to handle the toughest of mowing challenges. The grass will fly and the blades will spin as we dissect these two contenders.

Get ready to witness a cut above the rest.

Stamped Deck Vs Fabricated Deck

The difference between a stamped and fabricated deck is in how they’re made and how they work. A stamped deck earns its precision through the use of stamped metal, which allows for detailed craftsmanship. A fabricated deck gains its durability from being assembled with welded components, resulting in a structure capable of enduring challenges.

What is a Stamped Deck on a Lawn Mower?

A stamped deck on a lawn mower refers to the mowing deck’s construction method. This is where a single sheet of metal is stamped, bent, and formed into the shape of the cutting deck.

This method involves using a hydraulic press to create patterns and contours in the metal sheet. The result is a deck with various curves, slopes, and detailing that enhance the mowing process.

Stamped mower decks are known for their precision cutting and fine detailing. The stamped patterns on the deck assist in lifting the grass as the blades rotate, ensuring an even and clean cut.

The curves and slopes in the deck design also help with grass dispersion, preventing clumping and improving grass distribution.

Remember, regular maintenance and cautious operation are essential to maximize the lifespan and efficiency of a stamped mower deck.

Pros and cons of stamped deck

Pros

- Precision cutting. Stamped decks have patterns that aid in lifting the grass for a precise and consistent cut.

- Even dispersal. The contours and curves of a stamped deck help disperse clippings.

- Lightweight. Stamped decks are lighter than their fabricated counterparts, allowing for easier maneuverability.

- Cost-effective. Stamped decks are often less expensive to manufacture, which can lead to cost savings for consumers.

- Aesthetic options. Manufacturers can incorporate decorative patterns and designs into stamped decks.

Cons

- Less durable. Stamped decks are more susceptible to dents, bends, and damage from rocks, roots, or rough terrain.

- Maintenance. Due to their lighter construction, stamped decks require frequent maintenance and repairs.

- Limited strength. Stamped decks may struggle with heavy-duty mowing tasks or thick vegetation.

- Resale value. Over time, the aesthetics of a stamped deck may deteriorate more quickly than other types of decks.

- Noise. The construction of stamped decks can result in increased noise levels during operation.

What is a Fabricated Mower Deck?

A fabricated deck mower is made from a single sheet of metal stamped into shape. It’s constructed by assembling pieces of metal that are welded together to create the deck’s structure.

This construction approach allows for greater strength, durability, and customization. Fabricated decks are often made from thicker gauge metal, which enhances their ability to withstand rough terrain, impacts, and heavy mowing tasks.

The welding process used in fabricating these decks creates sturdy joints that contribute to the robustness of the deck. The increased strength of fabricated decks makes them well-suited for commercial use.

However, the welded joints can accumulate debris and moisture over time, leading to corrosion if not well maintained. Regular cleaning and maintenance are crucial to ensuring the longevity of a fabricated mower deck.

Pros and cons of fabricated deck

Pros

- Durable. Fabricated decks are highly durable and able to withstand rough terrain, impacts, and heavy use.

- Versatile. The flexibility of fabrication allows for customization in design, size, and features.

- Heavy-duty performance. Fabricated decks excel in heavy-duty mowing scenarios.

- Longevity. Due to their sturdy construction, fabricated decks have a longer lifespan compared to some other deck types.

- Enhanced strength. The welded joints provide superior strength, minimizing the risk of bending or warping.

- Reduced noise. Fabricated decks produce less noise during operation due to their solid construction.

Cons

- Weight. Fabricated decks are heavier than stamped decks, which can impact maneuverability.

- Costly. The increased materials and labor required for fabrication make these decks more expensive.

- Maintenance. Welded joints trap debris and moisture, leading to corrosion over time if not cleaned and maintained.

- Aesthetic limitations. Fabricated decks might lack the intricate patterns and designs available in stamped deck mowers.

- Potential corrosion. If not cared for well, the welded seams and joints become vulnerable to rust and corrosion.

- Complex repairs. In the event of damage, repairing a fabricated deck might involve more complex processes.

Stamped Vs Fabricated Deck: Head-to-Head Comparison

Fabricated deck vs stamped deck: Build quality

In terms of build quality, fabricated decks and stamped decks have distinct manufacturing processes.

Fabricated decks are made by assembling various metal components, which are then cut, shaped, and welded together. This method uses heavy-duty materials, around 11-gauge steel.

This approach is chosen to ensure the deck can withstand demanding tasks, such as heavy mowing in tough terrains.

Stamped deck mowers are formed from a single sheet of metal that’s pressed, bent, and molded to create intricate designs and shapes. Typically constructed from 12-14 gauge steel, stamped decks are lighter in weight.

This design aims to reduce the weight of the mower, allowing for smoother operation and less strain on the engine.

However, the lighter construction of stamped decks can make them susceptible to damage from accidental impacts.

Verdict: The choice between fabricated and stamped decks in terms of build quality hinges on the desired durability and the specific tasks the mower will handle.

Stamped deck vs fabricated decks: Weight

In the weight category, distinct characteristics emerge due to their construction methods and materials.

Stamped decks weigh less due to their single-layer molding process and use of lighter materials like 12-14 gauge steel. This deliberate lightweight design aims to reduce the weight of the mower.

As a result, mowers with stamped decks can be maneuvered easily and place less strain on the engine, allowing for smoother operation.

Fabricated decks tend to be heavier, often utilizing heavier materials such as 11-gauge steel. This increased weight contributes to their sturdiness and durability.

For this reason, they are well-suited for tackling tough mowing conditions and challenging terrains.

Verdict: If maneuverability and ease of operation are paramount, a stamped deck’s lighter weight is advantageous

Fabricated vs stamped deck: Metal thickness

Fabricated deck mowers have heavier metal thickness. It is around 11-gauge steel (approximately 0.1196 inches thick).

This thickness contributes to their robustness, thus suitable for heavy-duty tasks.

In contrast, stamped mower decks are made of lighter materials. They range between 12 and 14-gauge steel (approximately 0.1046 to 0.0747 inches thick).

Verdict: The verdict lies in your specific mowing needs.

Stamped mower deck vs fabricated: Durability

In matters of durability, the choice between a stamped and fabricated deck lies in their construction and materials. Fabricated decks excel in durability due to their heavy-duty build and use of thicker materials.

This thickness enhances their resilience, making them capable of enduring tough mowing conditions. Fabricated decks are well-suited for heavy-duty tasks and commercial use, offering longevity.

In contrast, stamped decks, while visually appealing with intricate designs, are less durable. Constructed from lighter materials, they are more susceptible to damage.

Verdict: Fabricated deck’s sturdiness makes it the preferable choice.

Stamped vs fabricated mower deck: Best usability

When evaluating the best usability between these two machines, several factors come into play.

Stamped decks shine in maneuverability and ease of operation due to their lighter weight and intricate designs. This makes them well-suited for flat and less demanding terrains.

Fabricated decks excel in heavy-duty usability, with their sturdier construction and thicker materials handling rugged terrains.

If you have a smaller lawn and prioritize ease of handling, a stamped deck is ideal. However, for larger areas or challenging conditions, a fabricated deck is ideal.

Verdict: Your choice should align with the specific demands of your mowing environment and the tasks you’ll be performing.

Stamped or fabricated deck: Affordability

Stamped decks have a lower manufacturing expense due to their simpler construction process and lighter materials. This translates to a more budget-friendly price tag for the mower itself.

Fabricated decks with their heavy-duty materials and welding requirements, have higher production costs and a higher price.

However, factor in the long-term benefits. Fabricated decks are durable. That means they offer better value over time due to reduced maintenance and longer lifespan.

If upfront affordability is a priority, a stamped deck mower is more suitable.

Verdict: If you’re looking for a durable investment, a fabricated deck could offer better value.

Stamped vs Fabricated Deck: Maintenance

Maintenance is a crucial consideration when comparing stamped and fabricated decks.

Stamped decks often require regular maintenance to preserve their appearance and functionality. They need periodic sealing to protect against moisture and stains.

Fabricated decks need less frequent maintenance due to their sturdier construction.

While both may need cleaning and debris removal, fabricated decks have fewer maintenance demands.

Verdict: If you’re seeking a deck with lower maintenance requirements, a fabricated deck is the preferable choice.

Stamped vs Fabricated Deck: Comfort and Safety

Stamped mower decks can sometimes become hot in direct sunlight due to their metal composition. This will lead to discomfort when walking near or touching the deck.

Additionally, stamped decks might be more prone to becoming slippery when wet, posing a safety risk.

Fabricated mower decks stay cooler under the sun and offer better traction when wet. This enhances both comfort and safety during operation.

Verdict: If you want a more comfortable and safer mowing experience, a fabricated deck suits your needs.

Fabricated mower decks vs stamped: Aesthetics

Comparing fabricated and stamped decks showcases distinct visual characteristics.

Stamped mower decks have intricate patterns, textures, and designs. This artistic detailing lends an appealing and personalized touch to your outdoor space.

Fabricated decks offer a more uniform and modern look. While they may lack the same level of decorative flair, fabricated decks come in various colors and finishes.

Verdict: The choice between the two depends on your aesthetic preferences.

Table: Fabricated Vs Stamped Decks Summary

| Key point | Stamped deck | Fabricated deck |

| Build quality | Lighter construction | Heavier, solid welded construction |

| Weight | Lighter, easier maneuverability | Heavier, potential impact on mobility |

| Metal thickness | 12-14 gauge steel, lighter | 11 gauge steel, sturdier |

| Durability | More susceptible to damage | Resilient, better suited for tough tasks |

| Best usability | Easier handling on flat terrains | Suitable for rugged terrains and heavy tasks |

| Affordability | Generally more budget-friendly | Potential higher upfront cost |

| Maintenance | Requires regular sealing and repairs | Lower maintenance demands |

| Comfort and safety | Can become hot and potentially slippery | Cooler, better traction when wet |

| Aesthetics | Intricate patterns, artistic flair | Uniform, various colors and finishes |

How Do I Know If My Mower Deck Is Stamped?

Determining whether your mower deck is stamped can be done by examining its construction and appearance. Here are some steps to help you identify if your mower deck is stamped:

Check the construction. Look at the edges and corners of the deck. Stamped decks often have visible seams or joints where different sections of metals are joined together.

Look for patterns. Stamped decks have patterns and designs pressed onto the metal surface. Examine the deck for repeating patterns or textures that suggest it has been stamped.

Observe the material. Stamped decks are made from a single sheet of metal that’s pressed into shape. If you can see the backside of the deck, you might notice that it’s a continuous sheet without noticeable welded joints.

Consider the weight. Stamped decks are lighter so if it’s lightweight, it might be stamped.

Consult the manual or manufacturer. Check the owner’s manual of your mower or visit the manufacturer’s website to find more information.

Seek professional advice. If you’re uncertain, consult a local mower dealer or professional who can inspect the deck.

Note: Mower deck construction varies between different brands. So, while these steps might help you make a guess, it’s always best to refer to the manufacturer’s information.

How Thick Should A Mower Deck Be?

The thickness of a mower deck can vary depending on factors such as the type of mower, the intended use, and the manufacturer’s design.

The thickness for riding lawn mower decks should be around 14 to 10 gauge, which translates to approximately 0.0747 to 0.1345 inches (1.9 to 3.4 mm) thick.

Heavy-duty commercial mowers are even thicker, ranging from 10 to 7 gauge or approximately 0.1345 to 0.1875 inches (3.4 to 4.8 mm) thick.

Are All John Deere Decks Stamped?

No. Not all John Deere Decks are stamped. They have both stamped and fabricated mower decks in their lineup.

The availability of stamped or fabricated decks can depend on the specific model and series of the John Deere mower.

Read also: John Deere vs Cub Cadet Lawn Mower.

What is Better, a Stamped or Fabricated Mower Deck?

When comparing stamped and fabricated mower decks, several factors come into play.

Stamped decks boast intricate patterns and precise cutting, making them visually appealing. They are also suitable for maneuvering on smaller lawns.

However, their lighter construction might render them less resilient.

Fabricated decks are more durable and sturdy excelling in heavy-duty tasks and demanding terrains.

Although they are more expensive and less easy to maneuver, their strong build guarantees durability and effective performance.

All in all, the decision between the two lies in your mowing needs.

FAQs

Which zero-turn mower has the best deck?

Does Cub Cadet have a fabricated deck?

Does Husqvarna have fabricated deck?

What is an iron-forged deck?

Stamped Vs Fabricated Deck Verdict

In conclusion, the choice between a stamped and fabricated mower deck comes down to your needs.

Both options have their strengths and trade-offs. Evaluate the factors at hand and select the mower deck that aligns best with your specific mowing requirements.

Go for a stamped deck lawn mower when:

Go for a stamped lawn mower deck when you need precise cutting and maneuverability, or have a smaller lawn with less demanding terrain. Stamped decks are visually appealing and suitable for lighter tasks.

Go for a fabricated deck lawn mower when:

Go for fabricated lawn mowers when you need durability, and strength for heavy-duty tasks, or when dealing with larger lawns or challenging terrains.

Fabricated decks excel in resilience and are ideal for demanding mowing conditions.