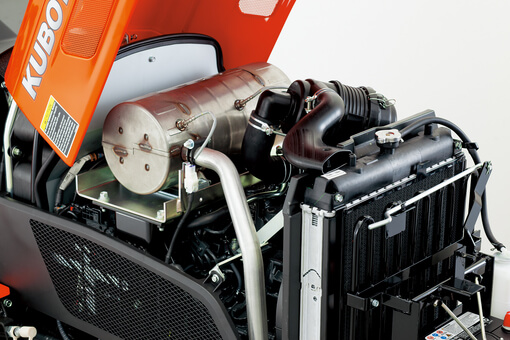

The days of diesel engines billowing thick black smoke from the exhaust system are long gone, thanks to modern Diesel Particulate Filters (DPFs).

These little devices trap 80% of diesel particulates, eliminating the black carbon elements in diesel engine emissions.

But, expectedly, the particulate filters occasionally fail. When this happens, a “regeneration” must empty or clean the DPF filter to restore normal function.

Except, the regeneration process can fail too! So, what happens if the regen process is problematic? Read on to learn common Kubota Regen Problems and how to fix them.

What is Regeneration?

DPF regeneration is the process of “burning off” the particles trapped in a DPF filter to increase operational efficiency and prevent breakdowns.

The process decomposes biologically active substances in the trapped diesel particulates, rendering them inert.

This process is important because a clogged DPF can cause issues. For instance, ash accumulation can damage your filters and cause engine failure.

How the Kubota Regen Process Works

The regeneration process on Kubota tractors and mowers depends on whether it’s a passive, active, or “forced” process.

Passive Kubota Regeneration

Passive Kubota mower regeneration is an automatic process that doesn’t require the driver’s intervention. It happens while you’re using the tractor and is signaled by a DPF light.

A passive regen light has eight dots and a symbol resembling a check engine light.

A word of caution – ongoing passive regeneration indicates that the exhaust gas is hot, the exhaust system is hotter, and the tailpipe is hot too.

So, don’t pull over or touch the exhaust system. However, if you must park, avoid tall or dry grass to prevent fire risk.

The passive regeneration process combines hot exhaust gases with a chemical coating or catalyst to heat the exhaust stream to oxidize the soot.

Then the process proceeds to a diesel oxidation catalyst (DOC), where a chemical reaction produces ash.

Read: Kubota L3560 Troubleshooting

Active Kubota Regeneration

Unfortunately, passive regeneration requires the unit’s internal system to be at a high temperature, usually 350C+, to trigger “burn-off.”

Thus the tractor must be mowing at 60-70km/hour. But most tractor drivers don’t use the equipment long enough or at the required speeds to achieve these conditions.

Thus, manufacturers devised an alternative DPF regeneration process that doesn’t require using the tractor for a long time.

This process, known as active regeneration, depends entirely on engine load in determining the best time to initiate regeneration.

Active regeneration is only necessary if passive regeneration fails for a while. If this happens, soot particulates deposit on the DPF.

Kubota tractors and mowers monitor the deposit levels via pressure and temperature sensors. For instance, more pressure indicates a higher resistance to flow, meaning a higher particulate load.

Whenever the load reaches a critical point, typically 45% of the tractor’s capacity, it automatically triggers active regeneration.

During active regeneration, raw fuel automatically enters the DOC, increasing exhaust temperatures around the DPF to over 600C, thus triggering soot oxidation and decomposition.

See: Kubota M5 111 Troubleshooting

Kubota regeneration problems

Unfortunately, auto regeneration sometimes fails in most kubota reviews. Typically, regeneration has failed if you notice the following;

- The engine refuses to start: Kubota’s high-efficiency engines refuse to start if they detect the excess buildup of fumes. This is a safety feature designed to protect the engine.

- Reduced fuel economy: When the DPF is blocked, exhaust fumes have no way out of the engine. This often causes incomplete combustion, resulting in fuel inefficiency.

- A weaker drive feel: A clogged diesel particulate filter can cause a weaker drive feel as the soot buildup suffocates the engine. The driver is forced to be heavier on gas, but the returns don’t match the effort.

Common Causes of Failed Kubota Regeneration?

Why does regeneration fail? That’s the most common Kubota regen question we get. The following are common reasons;

- Sensor Failure: Multiple temperature and pressure sensors lace Kubota’s after-treatment system, which monitors exhaust gases entering and exiting the DPF. The regeneration process may fail if one of the sensors is faulty.

- Short Drives: Regeneration (active or passive) occurs at very high temperatures. Unfortunately, the exhaust system can only reach the required temperatures if the tractor runs intermittently. Thus, short drives can compromise regeneration.

- Exhaust Gas Recirculation (EGR) valve issues: The EGR valve controls the recirculation of exhaust gases. Unfortunately, impurities in exhaust gases eventually clog the EGR system, impacting EGR valve movement. If this happens, the DPF clogs, causing regeneration challenges.

- Faulty engine: The Kubota engine and regeneration process are complementary systems. Therefore, just like regeneration issues impact engine performance, a faulty engine affects the regeneration process too. For instance, problems in the engine’s temperature or emissions control directly impact regeneration.

- Blocked Diesel Oxidation Catalyst (DOC): Excessive carbon buildup in the DOC chamber can block the system, restricting exhaust flow into the DOC and causing back pressure. This can cause regeneration failure.

- Dirty DPF – A clogged DPF is among the most common Kubota DPF problems. In turn, partial or complete blockages block exhaust gases from entering the filter, causing pressure buildup. Excessive pressure, if not quickly addressed, can cause a DPF crack and, consequently, failed regeneration.

- Other issues: Two other issues that may impact the Kubota regeneration process are turbocharger and hydrocarbon doser malfunctions. The hydrocarbon doser injects diesel into the exhaust during regeneration while the turbocharger forces compressed air into the combustion chamber. Thus, dirt buildup or damage to either can cause regeneration failure.

Recommended Reading: Kubota L3901 Troubleshooting

Kubota regeneration time

Kubota’s diesel engine regeneration process typically takes around 20 minutes, depending on the model and conditions.

During this time, the equipment can usually continue operating, minimizing downtime. It burns off the soot in the DPF, ensuring proper performance and reduced emissions. Follow safety guidelines provided by Kubota for optimal operation.

Fixing Failed Regen Issues on Kubota Tractors

The best way to address Kubota regeneration issues is to take your tractor to a professional mechanic for early diagnosis and repairs.

Alternatively, watch out for DPF indicator lights. This light signals failed auto (passive or active) regeneration. So, you must manually push the regeneration button to clean the DPF filter.

You can perform forced regeneration using the tractor or conduct a parked regeneration.

Whichever option, read your manual for step-by-step guidelines. For instance, you may need to ride the mower at 65mph for 20 minutes.

Note that forced regeneration requires the following conditions, without which it cannot begin;

- The fuel tank must be 20%+ full.

- The fuel light must be OFF.

- The engine management light must be OFF.

Diesel Particulate Filter (DPF) Cleaning on Kubota Machinery

However, don’t rely on the regeneration process to keep your Diesel Particulate Filter (DPF) clean.

Instead, it helps to manually clean the filter periodically to keep it clean and in the best working condition.

Indeed, Kubota recommends cleaning the DPF on all 2007 or later engines every 250,000 miles (400,000km) or after 6,000 hours or less of use.

Additionally, clean the After-Treatment Fuel Injector every 100,000 miles (161,000 km) or every 3,000 hours of use. Otherwise, you’ll soon need to replace these parts.

It’s best to schedule professional DPF cleaning to avoid further damage to the delicate filter.

Interesting read: Common Kubota GR2120 Troubleshooting

When to Replace the DPF Regeneration System

Any Kubota DPF filter that reaches 90% or a higher exhaust particulate accumulation must be replaced. Often, the engine refuses to work until you replace the filter.

However, the filter can last a long time if you regularly enable auto regeneration and the process, goes smoothly.

Typically, it lasts 2,500 regens This translates to 37,000 to 50,000 hours, given Kubota tractors require regeneration every 15-20 hours of use. DPF replacement costs $3,000+.

Kubota svl75-2 regeneration

The Kubota SVL75-2 has a diesel particulate filter (DPF) regeneration system.

The regeneration process typically takes about 20 minutes, burning off accumulated soot in the filter to maintain engine performance and reduce emissions.

During regeneration, the equipment can often continue operating to minimize downtime. Always adhere to Kubota’s safety guidelines for proper operation during this process.

FAQs

How Long Does Kubota Regen Take?

Kubota regeneration takes 20-30 minutes, though some take up to 45 minutes, depending on the severity of the soot accumulation.

This applies to parked or manual regeneration. Meanwhile, passive and active regeneration processes are automated processes that take anywhere up to 15 minutes.

How Do You Force a Regeneration on a Kubota Tractor?

To initiate forced regeneration on Kubota tractors, apply the parking brake and return the throttle to idle.

Then wait for the parked regeneration switch light to start flashing. At this point, press the Kubota auto-regeneration switch to initiate the regen process. The process is complete when the LED indicators go off.

How Can You Delete Regen on a Kubota Tractor?

Yes. You can delete, disable, deactivate, or remove the DPF regen and EGR exhaust gas recirculation system in modern Kubota tractors.

However, you can only do so using a third-party Kubota DPF emulator. One such product is available from the Canbus Elulator store. It clears warning signs and prevents common DPF regeneration errors for a smoother experience.

What Do You Do When Your Kubota Regen Light Comes On?

When your Kubota regeneration light comes on, it’s time to clean the DPF filter. First, park the tractor on a flat surface in a well-ventilated area with idle engines and shift levers neutral.

Then warm the engine and press and hold the Kubota regeneration switch for a few seconds to initiate the regeneration process.

Next, read on: Kubota l3301 problems and quick fixes.

Kubota Regen Problems Summary

The DPF regeneration process in Kubota diesel engines is critical to maintaining a healthy fuel combustion process.

Unfortunately, sensor failures, short drives, and EGR valve malfunction, among other Kubota DPF issues, can cause DPF regeneration failure, especially in cold weather.

If this happens, try forced regeneration and consult a professional if the issue persists.